The Ecstasy of Excellence

1. Achieving Zero-Defect Reliability with Design for Six Sigma (DFSS)

To move beyond reactive solutions, Ola should adopt Design for Six Sigma (DFSS) to aim for zero-defect reliability in their scooter designs. This approach focuses on preventing issues from occurring in the first place by embedding quality into the product design itself. The DFSS strategy would not only reduce the need for frequent maintenance but also elevate the overall customer experience.

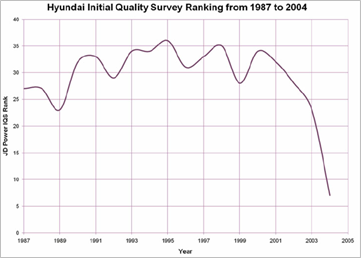

Let us take the case of Hyundai Motors. After consistently ranking in the 25-35 range over nearly a decade, it finally broke into the Top 10 list based on the JD Power Initial Quality Study (IQS) Ranking, as shown in the graph. Hyundai adopted Design for Six Sigma (DFSS) in 2002. This was supposedly verified by GM that had a variety of internal quality metrics, and collected benchmarking data from Hyundai. It was apparent that Hyundai’s quality assent was rapid, significant, and recognized by the customer. GM then adopted the structured DFSS activity employed at Hyundai Motors in Korea, which was claimed to be a key driver of the very dramatic rise in their quality.

2. Leveraging Six Sigma to Minimize Defects and Drive Quality Improvements

Let us take the case of Hyundai Motors. After consistently ranking in the 25-35 range over nearly a decade, it finally broke into the Top 10 list based on the JD Power Initial Quality Study (IQS) Ranking, as shown in the graph. Hyundai adopted Design for Six Sigma (DFSS) in 2002. This was supposedly verified by GM that had a variety of internal quality metrics, and collected benchmarking data from Hyundai. It was apparent that Hyundai’s quality assent was rapid, significant, and recognized by the customer. GM then adopted the structured DFSS activity employed at Hyundai Motors in Korea, which was claimed to be a key driver of the very dramatic rise in their quality.

2. Leveraging Six Sigma to Minimize Defects and Drive Quality Improvements

As Ola seeks to enhance product quality, adopting Six Sigma methodologies can be a game-changer in systematically reducing manufacturing defects. Six Sigma uses data-driven approaches to identify and eliminate the root causes of issues, aiming for near-zero defects in all aspects of the business. By integrating Six Sigma into both manufacturing and service processes, Ola can improve consistency, reduce variability, and deliver higher standards of excellence.

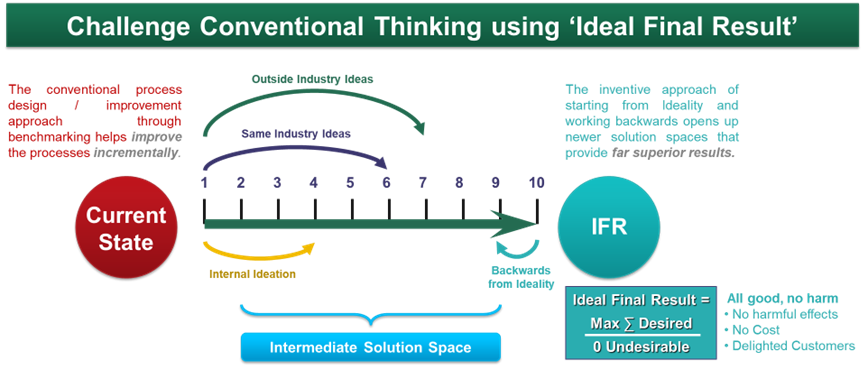

3. Achieving the Ideal Final Result (IFR): A Maintenance-Free Scooter

A visionary goal for Ola would be the pursuit of the Ideal Final Result (IFR)—designing a scooter that requires no maintenance or repairs at all. This approach challenges Ola to innovate beyond conventional designs, striving for breakthroughs in material durability, modular components, and AI-driven predictive maintenance.